Filament Detection is a function that activates when the filament runs out and isn’t changed. When triggered, the printing will stop. Follow the steps below to handle the operation after this function is activated:

|

|

|

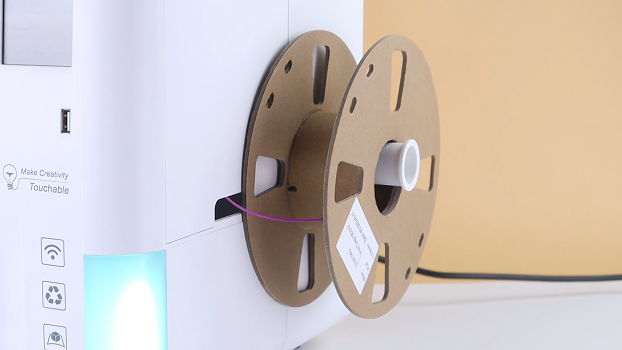

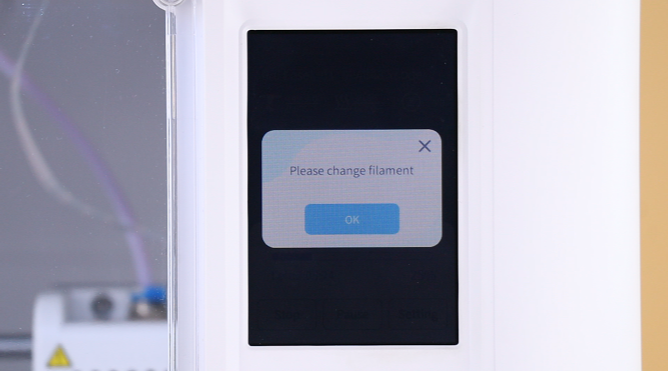

| 1.When the printer is working, remember to change the filament in time to ensure normal printing. | 2.If the filament runs out and isn’t changed, the Filament Detect function will be triggered. | 3.The printer will stop printing, emit a sound, and display a message to change the filament. Press OK. |

|

|

|

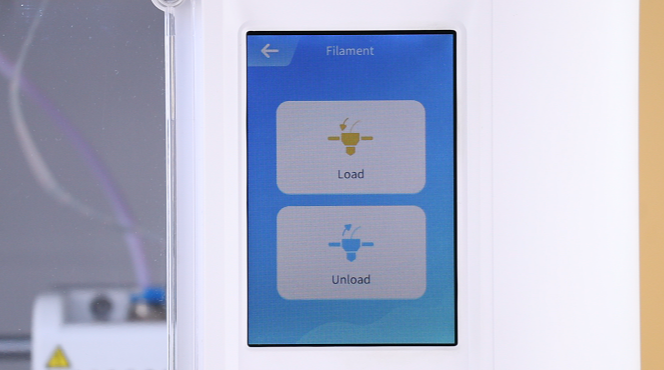

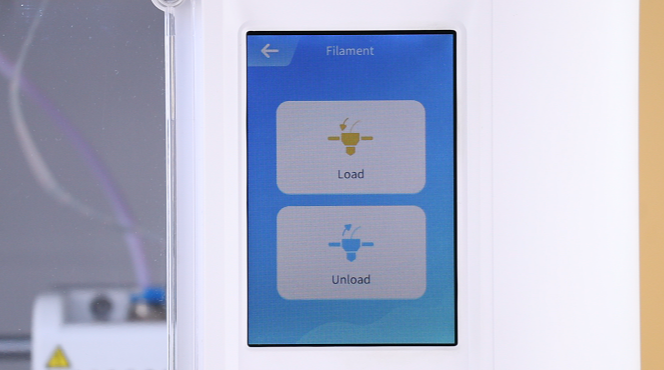

| 4.On the display, press Setting. | 5.Press Filament. | 6.Press Unload. |

|

|

|

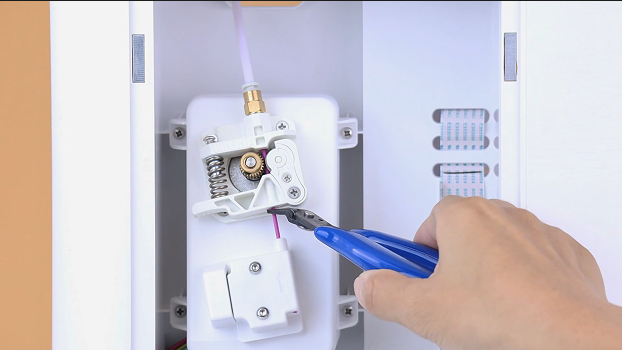

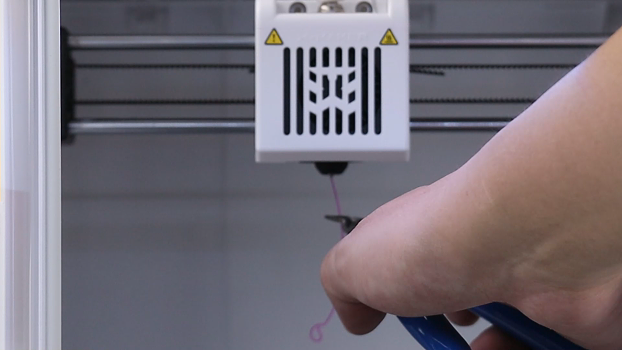

| 7.Read the tip and press OK. | 8.The nozzle will heat up automatically. | 9.Use pliers to cut off the filament extruded from the extruder. |

|

|

|

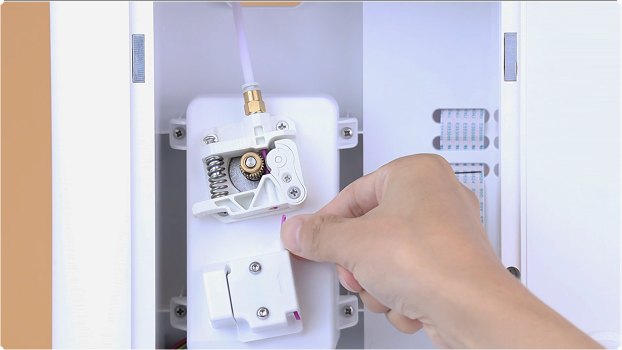

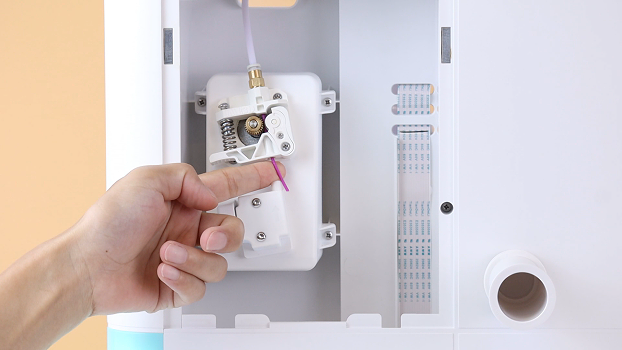

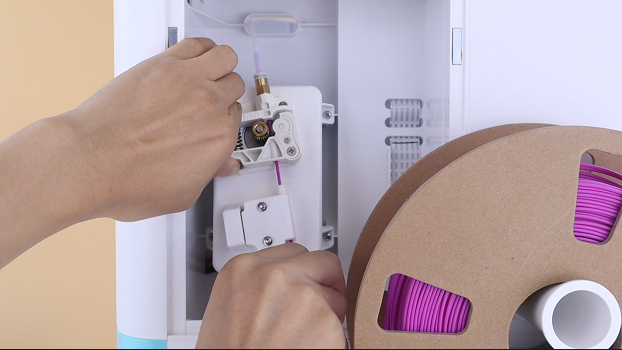

| 10.Remove the remaining filament for unloading. | 11.After the nozzle is heated, unloading will start automatically. | 12.Use your finger to push the filament outward to prevent damaging the components in the filament detection module. |

|

|

|

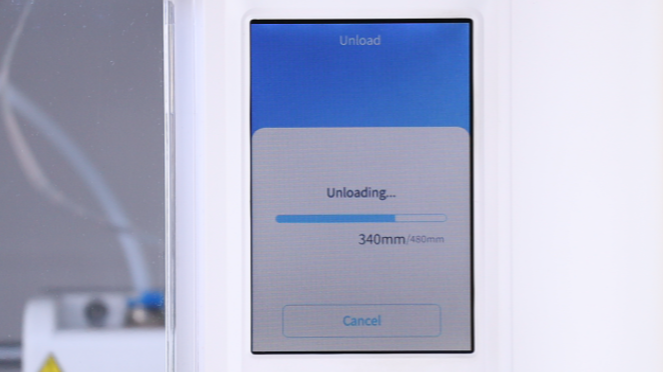

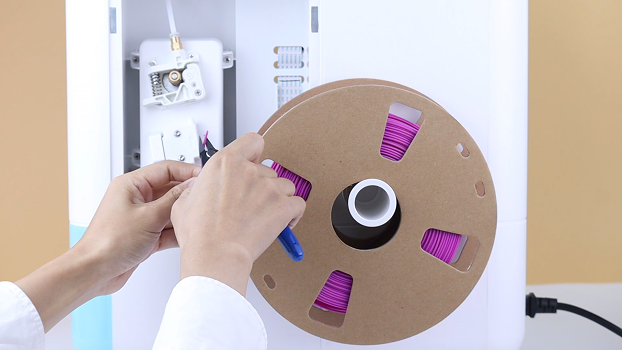

| 13.Wait for the the printer to complete filament unloading. | 14.Pull the filament out of the extruder. | 15.Take out a new spool and cut the tip at an angle. |

|

|

|

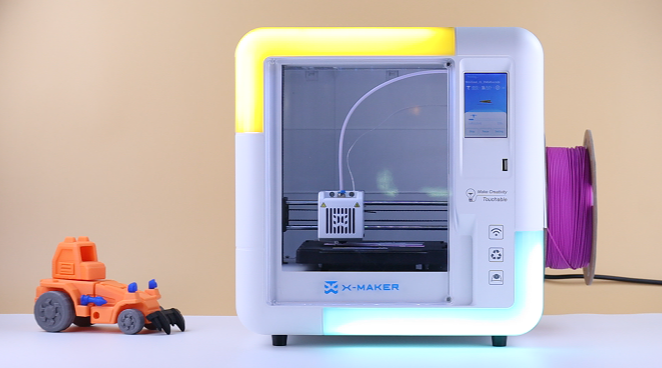

| 16.Straiten the tip and insert it through the gear and into the tube. | 17.Press Load. | 18.Wait for Loading to complete. |

|

|

|

| 19.After loading, cut the filament extruded from the nozzle. | 20.Press Continue. | 21.The printer will resume printing. |

Still have questions? Contact support via service@aoseed.com.