¶ Common Issues

1. Illusory layers

2. Filament not extruding

3. Printing defects

4. Machine stops mid-print

¶ Situation A

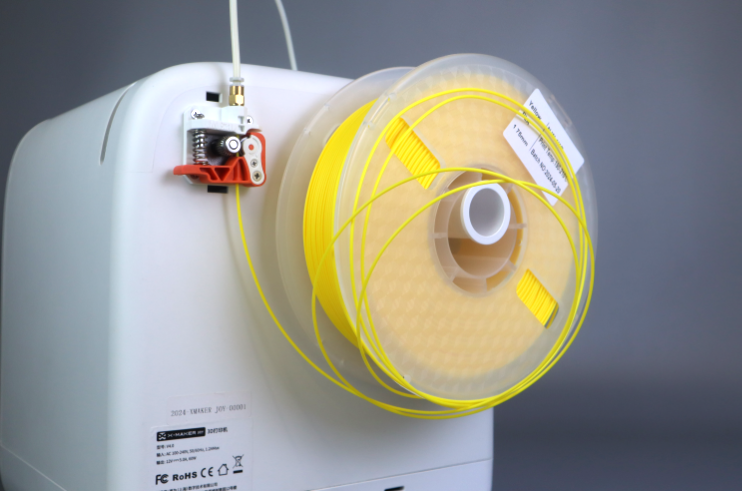

1) Filament is tangled or twisted.

2) Filament is too tightly loaded.

|

|

|

Cause:

The filament detection was not triggered, which causes the printer to complete the print job as if everything were normal. However, the resulting model is incomplete or contains broken or illusory layers.

Solution:

Rearrange or untangle the filament, then try printing again.

¶ Situation B

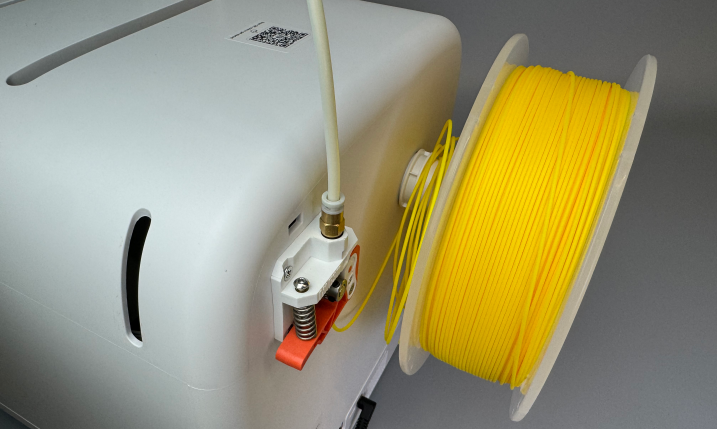

Filament loads correctly, but no filament comes out when printing begins.

Cause:

The print and bed temperatures were not adjusted when using non-AOSEED filament. As a result, filament detection was not triggered, leading to a print that appears complete but is actually faulty or partially printed.

Solution:

1. Use the needle in the toolkit to clog the nozzle.

2. Adjust the print and bed temperatures according to the recommended range on the filament packaging.

- For non-AOSEED filaments, it’s generally best to use the highest temperature in the recommended range.

- Both the X-MAKER App and X-PRINT slicer support these adjustments.

Still can't find what you're looking for? Contact us via service@aoseed.com.