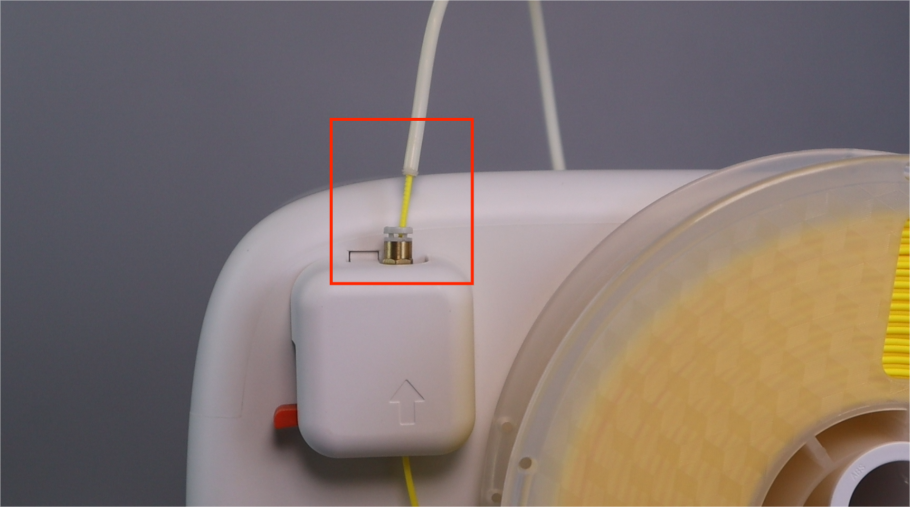

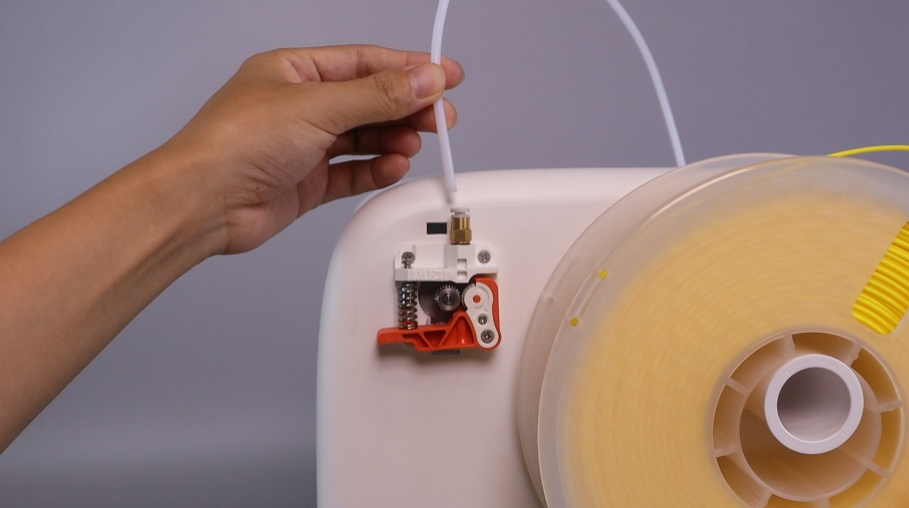

When printing, the tube may loosen and move upward, affecting filament feeding and printing. Follow these steps to resolve this issue.

|

|

|

|

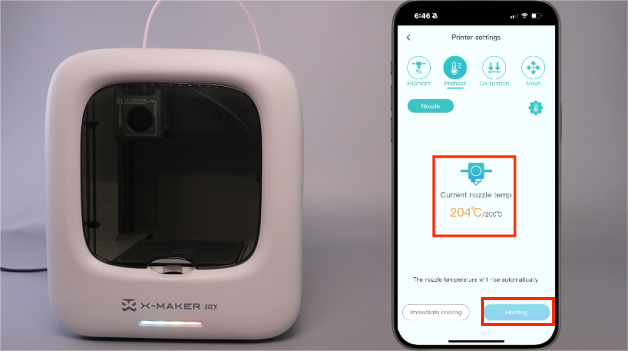

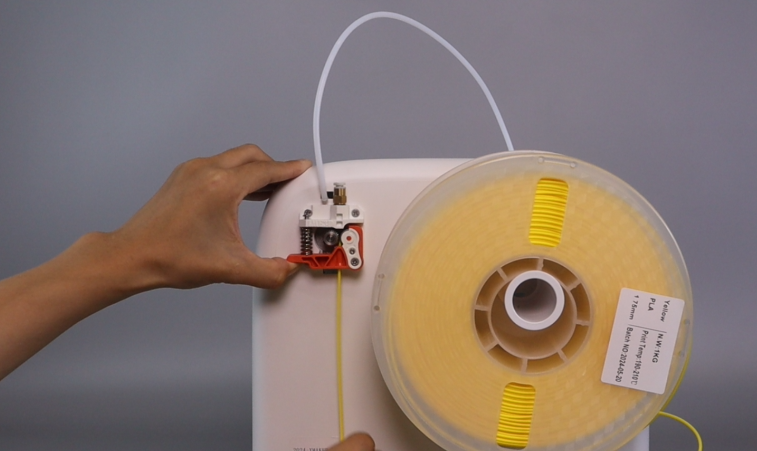

| 1. You find that the tube is not connected the pneumatic connector and moves upward when printing. | 2. Preheat the nozzle to 200°C. | 3. Once preheating is complete, pull the filament out of the extruder. |

|

|

|

|

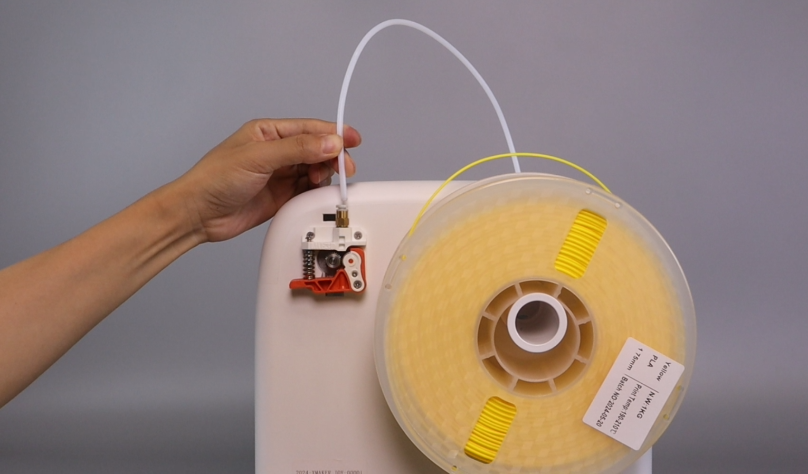

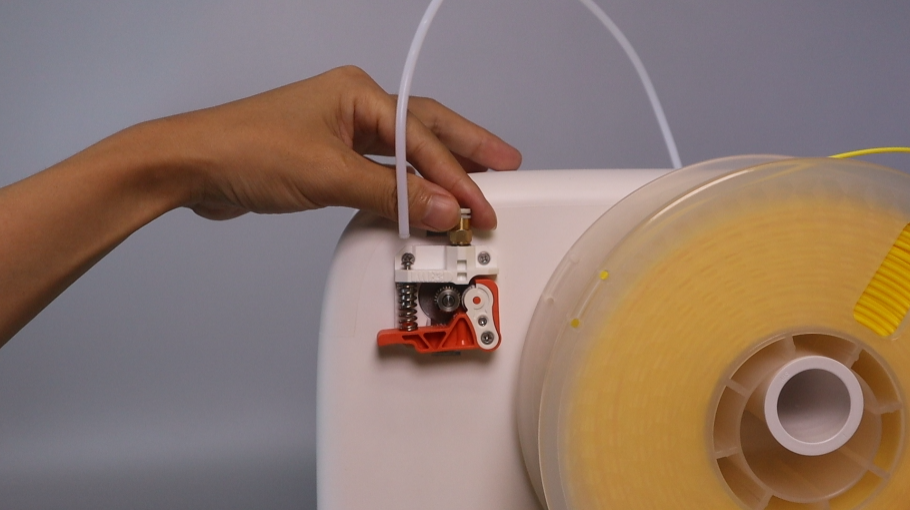

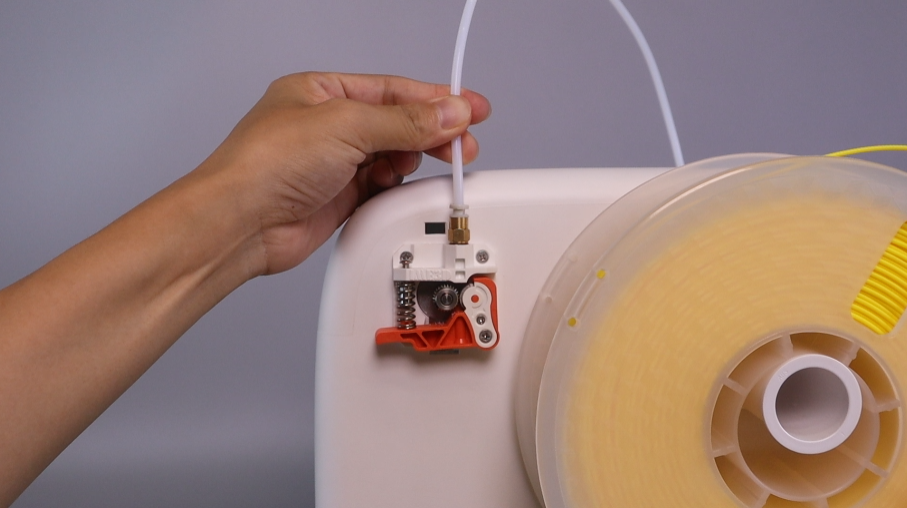

| 4. Reinsert the tube into the pneumatic connector. | 5. Lift the tube to check if it is properly secured. If the tube stays in place, you can reload the filament and resume printing. | 6. If the tube still slides upward, the pneumatic connector may need to be replaced. |

|

|

|

|

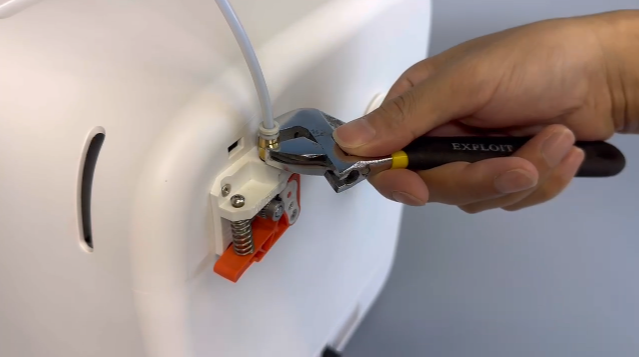

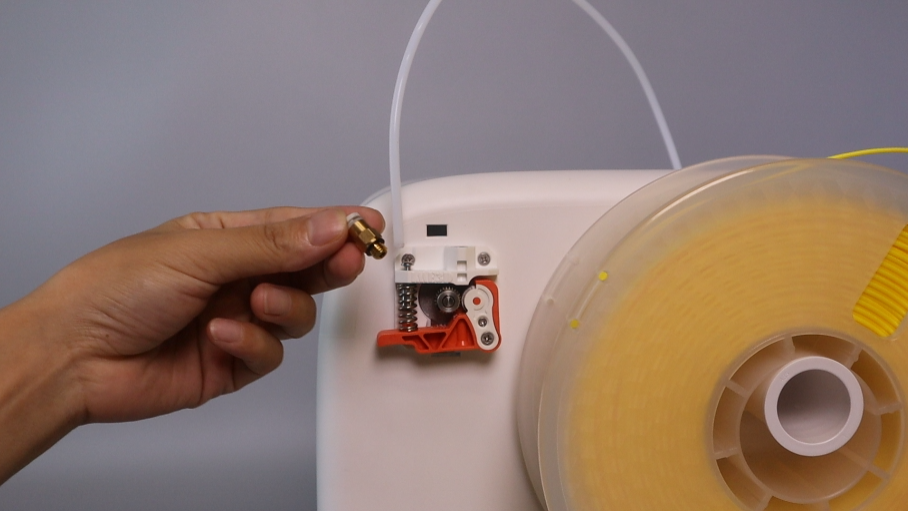

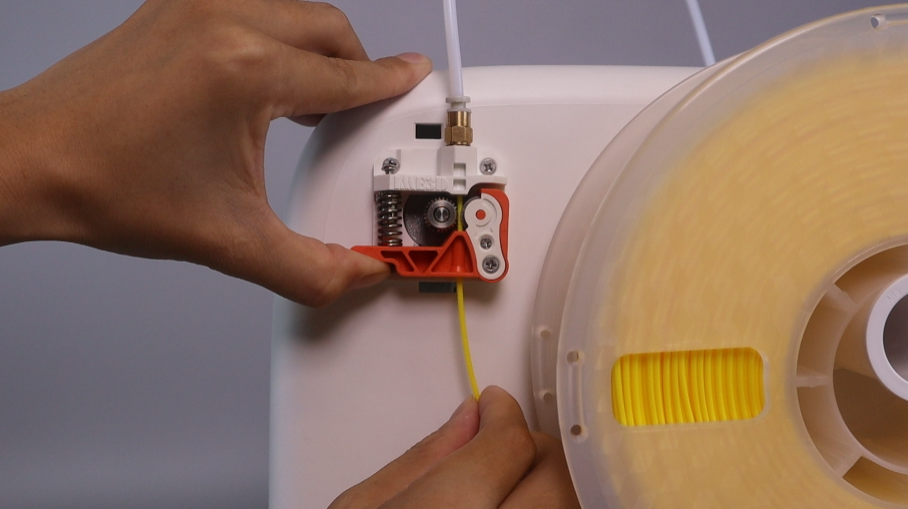

| 7. Use an adjustable wrench to loosen, | 8. and remove the pneumatic connector. | 9. Take out a new pneumatic connector. |

|

|

|

|

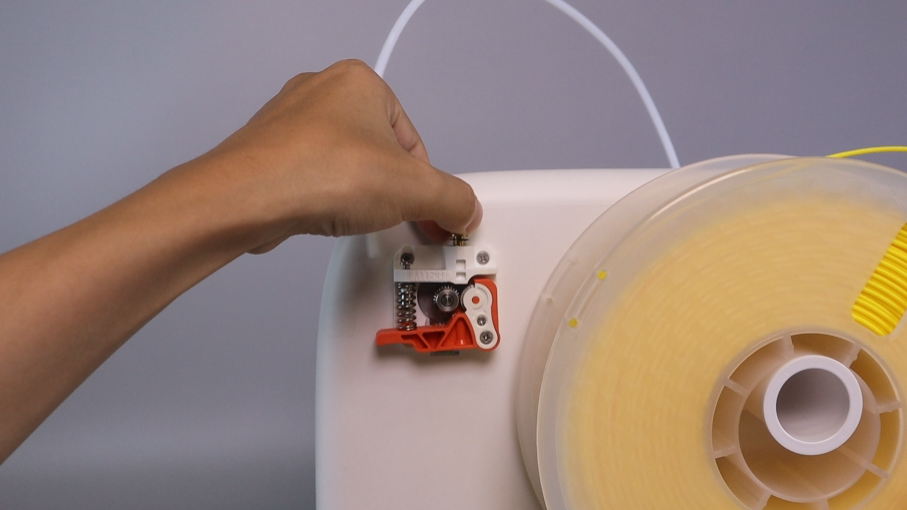

| 10. Install a new pneumatic connector by winding it into place. | 11. Reinsert the tube into the new connector. | 12. Lift the tube again to ensure it is properly fixed. |

|

||

| 13. If it is secure, you can reload the filament and start printing. |

Still have questions? Contact support via service@aoseed.com.